Welcome to the official website of SEASTARS CORP.,LTD.

Solution of simulation environment in Avionics test system

- Categories:Electronic System Simulation

- Author:

- Origin:

- Time of issue:2021-08-23 10:33

- Views:

(Summary description)In the process of design, development and test of avionics airborne equipment, it is necessary to have the support of simulation technology: Using simulation technology, the system prototype can be constructed quickly according to the system design scheme, and the design scheme can be verified; Using the simulation results, the product can be debugged in the system development phase, and the sub-system can be simulated and tested when the system development progress is not consistent.

Solution of simulation environment in Avionics test system

(Summary description)In the process of design, development and test of avionics airborne equipment, it is necessary to have the support of simulation technology: Using simulation technology, the system prototype can be constructed quickly according to the system design scheme, and the design scheme can be verified; Using the simulation results, the product can be debugged in the system development phase, and the sub-system can be simulated and tested when the system development progress is not consistent.

- Categories:Electronic System Simulation

- Author:

- Origin:

- Time of issue:2021-08-23 10:33

- Views:

Overview:

In the process of design, development and test of avionics airborne equipment, it is necessary to have the support of simulation technology: Using simulation technology, the system prototype can be constructed quickly according to the system design scheme, and the design scheme can be verified; Using the simulation results, the product can be debugged in the system development phase, and the sub-system can be simulated and tested when the system development progress is not consistent.

PROGRAMME CONTENT:

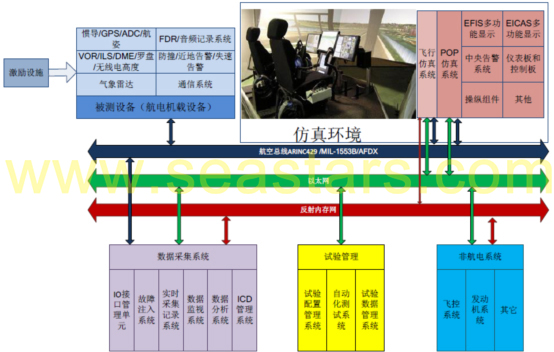

The policy environment for Avionics testing is mainly based on the flight simulation system, which is controlled by cockpit control components to provide the data of each module of the aircraft to the POP simulation system and the terminal simulation equipment respectively, implement POP simulation and 1553/AFDX/422 bus data flow simulation.

Main application areas:

◇Simulation and design verification of Avionics System;

◇Acceptance Test of each subsystem of Avionics System;

◇ Intersystem Integration and verification testing;

◇ Integrated Ground Test and verification of Avionics System;

◇ Aircraft Level Integration and validation.

Flight Simulation System

Flight simulation system is an important equipment in avionics and embedded training system dynamic simulation environment, which provides dynamic data for test. By acquiring the control information of the driving stick, throttle stick and pedal in the simulated cockpit, and according to the set aerodynamic characteristics and motion equations, the simulation and calculation are carried out, generate real-time position information, attitude information and other flight parameters of the aircraft, then, the data are transmitted to the relevant equipment or system in the avionics and embedded training system through Ethernet, reflective memory and aviation bus, and the dynamic integration test of the system is realized.

Pop simulation system

Pop simulation system is used to verify the rationality of man-machine interface design and display resource allocation, the correctness of operation mode conversion and picture switch, the rationality of picture layout and the correctness of characters and symbols. Through simulation, the defects in POP files are found and solved, the POP is optimized, and the man-machine efficiency is improved. Pop simulation system is mainly based on VAPS XT, VAPS XT is also a PC-based human-computer interface software for aviation, which has the characteristics of graphic design, automatic code generation, nCOM communication interface and so on.

Simulation of bus data flow

Based on the real-time flight attitude, position data, atmospheric data and navigation information generated by the aircraft model, and combined with the ICD definition of the aircraft, various flight parameters are converted into the bus signal of the avionics system through the hardware board card, the bus data flow simulation of avionics system is realized, and together with other real avionics equipment, an integrated test platform is constructed.

These include:

◇ ICD Database

◇ Bus Data Simulation of avionics system

◇ ARINC429 bus data simulation

◇Data simulation of MIL-1553B bus

◇AFDX bus data simulation

◇ RS422 data simulation

Real-time data acquisition and recording system

The real-time data acquisition and recording system is the core of the acquisition and testing system. Based on the real-time computer and various IO cards, the test program and test program are run, to achieve the Integrated Avionics System Dynamic and static environment of the collection and recording of various signals.

Data analysis system

The data analysis system is specially designed for the avionics test system. Based on the real-time data acquisition and recording module, a large amount of data is transferred to the data analysis system through the real-time reflective memory network, real-time Data Monitoring, data analysis, data recording, data playback, Data post-analysis, data export and other functions. During avionics system testing, the selected monitoring variables or signals are displayed in real time.

Display Signal type:

◇ Arinc 429

◇ MIL-1553b

◇ AFDX

◇RS422 serial port

◇ A/d analog quantity

◇ Dio Dispersion

Display:

◇ Tabular display

◇ Graphic display

◇Curve display

◇Indicator light

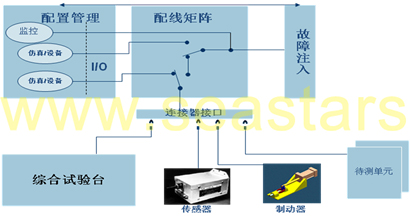

Wiring Matrix and fault injection

The main purpose of the distribution matrix is to realize the mapping of UUT signal and standard test equipment resource, which consists of four parts:

◇ Signal access connection panel

◇Signal conditioning unit

◇ Signal switching unit

◇ Unit under test (UUT) connection panel

During the development of Avionics test and simulation system, in order to meet the requirements of error insertion, monitoring and self-test, it is necessary to access each signal line connecting the test system and the system to be tested manually or automatically. Fault injection system provides modular panels and a large number of software-controlled error injection functions, which can simplify and speed up hardware in-the-loop testing, analysis and integration.

FEATURES:

◇Manual interrupt

◇ Software control error injection

◇ Insert a resistor into the signal path

◇ Insert a resistor between two signals

◇ Connect the four signals

◇Open a signal channel

◇ Connect the signal to the multimeter

◇ Connect the signal to the function generator

Test Management

The test management system realizes the data communication with each test sub-equipment through high-speed Ethernet to achieve the remote control of each sub-system and the upload of test results. Automated Test Systems perform specific test tasks.

Automated Test System

Automated Test System (TPM) is a comprehensive set of software tools that can manage the whole life cycle of avionics testing. TPM can help testers declare test requirements, create test cases, test plans, perform tests, generate test reports, and analyze data throughout the testing process.

Main advantages:

1. Use a simple set of tools to test throughout the life cycle, reducing costs 2. Reduce testing process based on intuitive test definition

3. Can Be fully traceable from system requirements to test results

4. In all phases of the testing process, a high degree of automation is used to increase productivity by

5. Improve test quality by using consistent tests in the same test process

Category: Electronic System Simulation

Scan the QR code to read on your phone

Contact Us

14th Floor, Block A, China International Science & Technology Exhibition Center, 12 Yumin Road, Madian, Chaoyang District, Beijing