Welcome to the official website of SEASTARS CORP.,LTD.

Virtual Reality human-machine assembly simulation and verification system

- Categories:Zevi Interactive Virtual Training Platform

- Author:

- Origin:

- Time of issue:2021-08-25 13:27

- Views:

(Summary description)The system combines the human motion tracking device with the engineering simulation application software to realize the real-time human-computer interaction simulation, through the high-end Optical motion capture package, and with the Haption force feedback device or RTID package, users can experience the leading edge of virtual assembly simulation in vision, touch, and interaction. For the product assembly and maintenance validation, new entry engineer training and other aspects have important engineering value.

Virtual Reality human-machine assembly simulation and verification system

(Summary description)The system combines the human motion tracking device with the engineering simulation application software to realize the real-time human-computer interaction simulation, through the high-end Optical motion capture package, and with the Haption force feedback device or RTID package, users can experience the leading edge of virtual assembly simulation in vision, touch, and interaction. For the product assembly and maintenance validation, new entry engineer training and other aspects have important engineering value.

- Categories:Zevi Interactive Virtual Training Platform

- Author:

- Origin:

- Time of issue:2021-08-25 13:27

- Views:

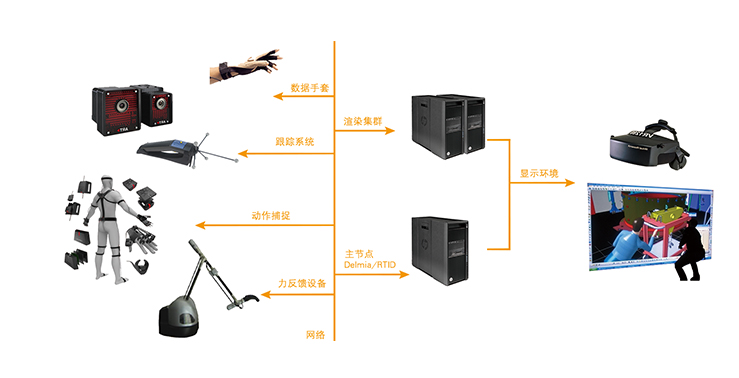

The system combines the human motion tracking device with the engineering simulation application software to realize the real-time human-computer interaction simulation, through the high-end Optical motion capture package, and with the Haption force feedback device or RTID package, users can experience the leading edge of virtual assembly simulation in vision, touch, and interaction. For the product assembly and maintenance validation, new entry engineer training and other aspects have important engineering value.

System composition

Hardware:

PC CLUSTER GRAPHICS CLUSTER, Optical Tracking System, data glove, data clothing, force feedback equipment, etc.

Display Environment:

Virtual Reality Environment, immersive HMD display, stereo liquid crystal display, etc.

SOFTWARE APPLICATIONS:

Delmia V5、RTI for Delmia、Conduit for V5

Based on the ARTTrack optical positioning and tracking equipment, the system uses DELMIA virtual simulation platform and Rtid human-machine engineering real-time Interactive System as the core driving engine to realize real-time 3d virtual assembly content and process, through the virtual reality environment to display in three-dimensional way to the user, and through the Haption force feedback device for virtual assembly verification or virtual maintenance verification.

System characteristics

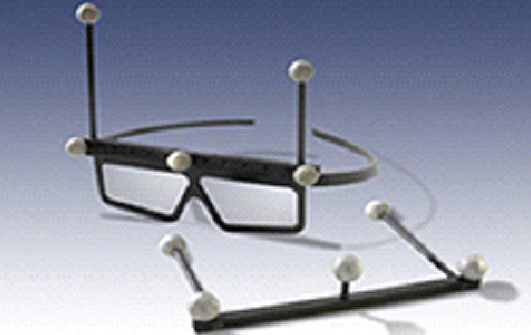

High Performance Professional Grade Optical tracking system

PC controlled mainframe

○Standard frame structure, easy to install and maintain

○ 6-dof position and direction for computer tracking

○Equipped with SYNCCARD2, can achieve multi-camera synchronous operation, and according to the need to install stereo glasses and other external components

Tracking Cameras

○High precision position and direction measurement

○No optical chroma-luminance interference between cameras

○Through the local area network to achieve low delay, high-speed data transmission

○It can resist the interference of magnetic, electric and sound waves

○Optimization solution for CAVE environment

○Up to 16 different types of cameras can be installed

Target and Mark Point

○Virtual reality dedicated interactive devices, such as Flystick2, fingerprint tracking

○Can carry on the target point the user custom, and can quickly carry on the target point the calibration

○Non-interactive objects of various shapes, including stereoscopic tracking points and head-mounted device tracking points

Virtual Assembly or virtual maintenance simulation development

Virtual Assembly of DelmiaV5 digital prototype

According to the shape characteristics and precision characteristics of product design, the assembly process of product is simulated realistically, and the users are allowed to control the virtual assembly of product in an interactive way, so as to check the assemblability of product and analyze the rationality of product design effectively, maintainability analysis, maintainability demonstration and verification, maintenance process verification, maintenance training implementation, etc. . The features are as follows:

○Dynamic cross-section check

○Assembly process planning

○Collision, interference check

○Visual inspection of man-machine Assembly

○Testing Assembly tools and human accessibility

○Check Motion Assembly tool

△ Built-in collision-free solver to automatically generate collision-free assembly paths

RTID Ergonomic real-time interaction

RTID is an extension of DELMIA V5 software, which can simulate the digital human body model in real time and interactively in virtual environment. Reduce the time required for Delmia to produce human movements; improve development efficiency, quality, and simplify the development process with the following features:

○Real-time physical simulation

○Real-time motion and motion constraints

○Capture and record of simulation process

○A manipulable simulation

○Support and management of operating equipment

○Operability

Conduit for V 5 immersive experience

Conduit was developed by Mechdyne for Dassault V5 products. Based on a distributed architecture, the middleware enables multi channel, large scene immersive browsing and interaction with raw V5 data. Features are as follows:

○Support 3D menu in VR environment

○Support Multi-person, multi-view tracking

○Enhance the real-time interactive frame rate of the cluster

○Support for digital simulation interactive process recording

○Support for immersive browsing of V5 raw data

○Support Remote and Lan Collaborative Review

○Meet the VR visualization requirements of virtual prototype assembly, design review, simulation and analysis

Scan the QR code to read on your phone

Contact Us

14th Floor, Block A, China International Science & Technology Exhibition Center, 12 Yumin Road, Madian, Chaoyang District, Beijing